CO2

Our world faces major, complex and urgent challenges. High CO2 emissions are leading to climate change and our natural resources are becoming increasingly scarce. This requires a different way of producing and consuming. By recycling complex products, Riwald Recycling forms a connecting link in the circular economy and we ensure significant CO2 savings in the chain.

CO2 reduction through innovation & policy

The contours of our business strategy lie in the Circular Framework and Trias Energetica.

We link our sustainability strategies to the Sustainable Development Goals (SDGs) and we integrate innovative technologies for maximum raw material efficiency.

Circular chain & Riwald Recycling

- The circular chain of Riwald Recycling

The core business of Riwald Recycling is the recycling of e-waste, ferrous and non-ferrous metals into high-quality raw materials for metal producers worldwide. As one of the world's leading metal recycling companies, Riwald Recycling plays a pivotal role as a supplier in the circular chain of sustainable material use worldwide. In our circular supply chain we have many contacts with private, public and knowledge institutions regarding high-tech and circular recycling.

On the purchasing side, Riwald Recycling has contacts with a wide range of suppliers, including industrial companies, OEMs, demolition companies, utilities, integral waste treatment companies, traders, car dismantling companies and national and regional governments. The smelters, finishers and OEMs are the buyers of our recycled sustainable raw materials.

Thanks to our method of collection, efficient operations, in-house production process and geographical locations, Riwald Recycling occupies a prominent place in the metal recycling industry in the Netherlands and the rest of the world. As a result, Riwald Recycling makes a direct contribution to protecting people, the environment and safety. The biggest advantages of our circular and high-tech recycling process are:

- Significant decrease in emmissions of greenhouse gasses under which CO2

- Sustainable reuse: metals are infinitely recyclable

- Reduction of environmental damage compared to mining

- Recovery of critical metals for the energy transition

Riwald Recycling & CO2 Reduction

- Circular entrepreneurship with the 9R strategies

Riwald Recycling strives for a circular economy with 100% recycling. Our aim is to become a 'circular hub' where all flows come together in our ecosystem: to transform complex products into pure raw materials and to transport them in a logistically sustainable manner to companies in the (manufacturing) industry. The economy would then run on recovered raw materials and no more 'new' raw materials would be needed. We do this together with a passionate team and together we have been working together since 1989 from various locations in the Netherlands on our mission with the highest priority for quality, sustainability and the environment. We pay attention to a cleaner environment and our R&D team continuously researches new innovations and possibilities to recycle waste flows as efficiently as possible into new raw materials.

As a crucial link in the circular chain, Riwald Recycling is aware of the possible consequences of its activities with regard to quality, sustainability, the environment and the safety of its employees, suppliers and visitors. Riwald Recycling is constantly looking for opportunities for a more energy- and environmentally friendly way of working and the pursuit of continuous improvement. We do this together with our partners and together we contribute to achieving common goals by conducting fundamental research into creating robust and efficient local energy systems.

In addition, the management and staff of Riwald Recycling consider it important to contribute to the reduction of CO2 emissions, the major cause of climate change. We have therefore chosen to make efforts ourselves to reduce our own CO2 contribution. Certification for the CO2 Performance Ladder is an important tool for us. Together with our partners, Riwald Recycling actively participates in CO2 reduction initiatives, in which we share knowledge about CO2 reduction across our sector and can continue to learn from each other.

- Circular Hub

- Reduction intern- and extern- CO2-emissions

- Centre for Energy Innovation

- Trias Energetica & energy transition

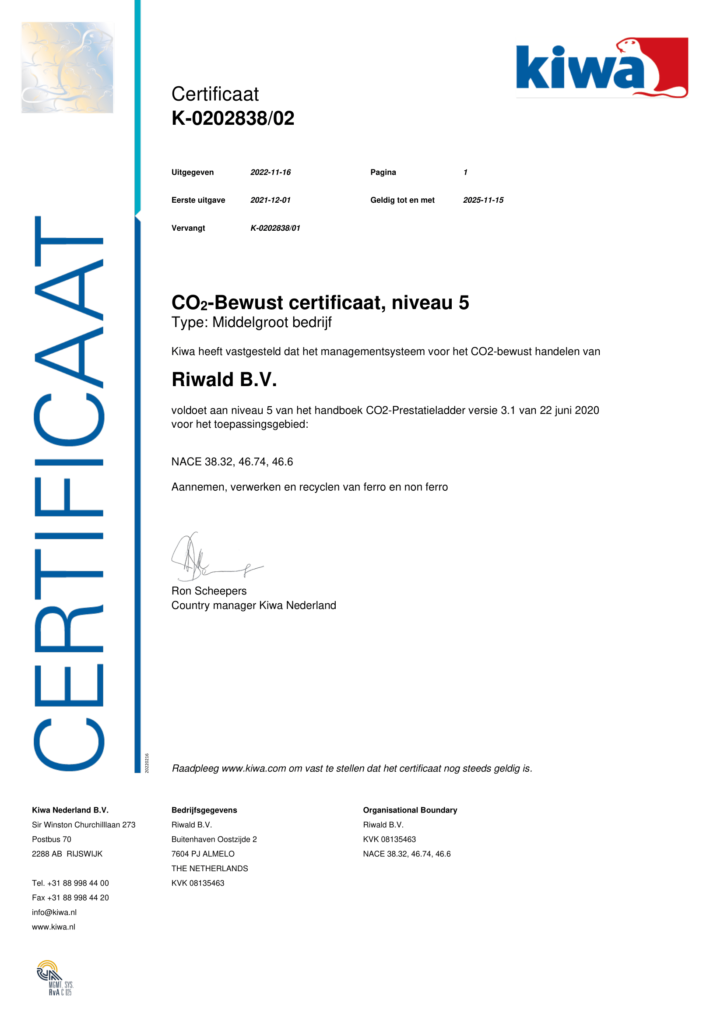

CO2-Prestatieladder & Riwald Recycling

- Reducing CO2 emissions in-house and out-house

Our policy is aimed at continuous improvement and at the further prevention, reduction or management of negative environmental impacts of existing and future business activities. A constant balance is sought between human well-being, ecological preconditions and economic ones. As a company, we therefore have the overall goal of optimizing our energy management. In connection with this, it was decided to set up the CO2 Performance Ladder.

Using the CO2 Performance Ladder, we have set up a system with which we can achieve this goal by measuring, registering, monitoring and adjusting our energy consumption (and therefore our CO2 emissions).

We will communicate our energy policy, CO2 footprint and our reduction targets internally and externally every six months. We will also provide information about our participation in the chain or sector initiatives in the field of CO2 reduction.

The level at which we deal with CO2 reduction meets the requirements set by the SKAO/CO2 Performance Ladder for level 5.

- Energy efficiency for maximum recovery

- Role model within the circular supply chain and energy transition

- R&D and innovation to reduce CO2 emissions

- One of the most sustainable recycling companies

High-tech equipment & sustainable fleet

High-tech equipment & sustainable fleet from Riwald Recycling for maximum raw material efficiency due to our Granulator, Infrared (NIR), X-ray, metal sensors, NF fines processing and colour sortings

CO2-documents & downloads

On this page you will find various documents in which you can read more about where we are now with regard to our so-called CO2 Footprints (from 2018) and which measures we have planned or initiated to reduce the CO2 emissions of our business activities.

CO2- reduction projects & sector- and chain initiatives

In addition to gaining insight into the CO2 emissions of Riwald Recycling, Riwald Recycling also participates in several projects and initiatives to reduce CO2 emissions in the entire chain together with other parties. This is achieved by sharing knowledge and experience in the field of conscious and responsible energy consumption plus R&D into newer techniques and applications within the recycling industry for maximum resource efficiency.

Riwald Recycling & sustainable fleet

From 2021 onwards, Riwald Recycling will transport with the latest Volvo FH trucks equipped with a highly efficient engine and a Long Haul Fuel package, consisting of innovative options, including I-See, I-Save and I-Shift for optimal fuel economy. In addition, Riwald Recycling also transports with the brand new Scania Next Generation 2021 model: digitization with the aim of energy profitability and a future in which the use of fossil fuels is a thing of the past. With these investments, Riwald Recycling contributes to sustainable (inter)national metal transport and we reduce our CO2 emissions and our CO2 footprint.

Riwald Recycling & sustainable operations

Riwald Recycling is expanding with an electric Sennebogen 8160 EQ balance crane that is equipped with the latest innovations for efficient operations. This project is an example of our 'electrification policy', in which fossil-powered machines and vehicles are substituted for electrically-powered machines and vehicles. Thanks in part to the intelligent distribution of energy, this balance crane consumes less energy than regular cranes, leading to considerable energy savings within the business process. With these investments, Riwald Recycling contributes to sustainable machinery and we reduce our CO2 emissions and our CO2 footprint.

Riwald Recycling & Bonaire case

We would like to share our vision and knowledge within the Kingdom of the Netherlands, including Bonaire. Bonaire faces significant challenges in the field of (metal) waste processing. Waste processing infrastructure needs to be improved and investments in recycling are a high priority. Due to the urgency and the demand for an even more sustainable waste policy, the Lieutenant Governor of Bonaire, Edison Rijna, visited Riwald Recycling, where Riwald plays an active role in finding solutions to Bonaire's environmental issues. Riwald Recycling links its sustainability strategies to the Sustainable Development Goals (SDGs) and integrates innovative technologies for maximum recovery from raw materials. The first containers with e-waste and scrap are being loaded in Bonaire for transport to the Netherlands, and Riwald Recycling is responsible for the transformation of complex products into pure raw materials.

Riwald Recycling & AELS

AELS (Aircraft End-of-Life Solutions) specializes in the reuse and recycling of aircraft parts, with the aim of approaching the recycling of commercial aircraft in a fully circular way. When all usable parts have been removed from the aircraft, there is always material left over, mainly the aluminum fuselage of the aircraft. AELS has started a collaboration with Riwald Recycling in order to use these materials from the aircraft in a high-quality manner. Riwald specializes in metal recycling and in this collaboration ensures that the special aluminum alloys of the aircraft are recycled. The collaboration between AELS and Riwald is distinguished by the innovative way of recycling the aluminum. This metal has a different alloy than regular aluminum. Riwald can process this metal in this way, making it a raw material for new aluminum again. This recycling method is in line with AELS' objective to reuse or recycle all aircraft in a fully circular manner.

Riwald Recycling & Klimaatplein

Riwald Recycling's circular solutions have a prominent place in the metal recycling industry within the Netherlands and the rest of the world. Riwald Recycling is the "circular hub" for metal flows. Nowadays, these solutions are also visible at the Klimaatplein. On a monthly basis, the Klimaatplein is visited twenty thousand times by organizations that want to do more sustainable business. Visitors will find many practical stories from companies that actively reduce their CO2 emissions and/or do circular business. Riwald Recycling is not only a partner, but also a participant in the Climate Action Alliance of the Klimaatplein. This Alliance consists of 70 SMEs that jointly work on a 40% CO2 reduction within 5 years.

Riwald Recycling & 100% circular Netherlands

The Dutch government is fully committed to a circular economy. She does this from the government-wide program Netherlands Circular in 2050. Since 2014, she has been uniting forces with various social organizations that want to accelerate the transition to a circular economy. All these collaborations form the basis of the Acceleration House Netherlands circular! Entrepreneurs, employees and those interested in the circular economy meet on the 100% Netherlands Circular platform. Moreover, 100% Circular Netherlands ensures that they can come into contact with experts from the business community, knowledge institutions and government. In the field of metal recycling, Riwald Recycling plays an important role with regard to circularity, energy efficiency and CO2 reduction. Given its position, expertise and separation technologies, Riwald Recycling plays an active role in finding solutions to global environmental issues.

Participation in the inspiration journey: Energy Management Systems/AI

In recent years VEMW, RVO and the NVDE have organized various inspiration tours to share knowledge and practical experience of the possibilities for reducing CO2 in industry. Companies were visited in a (CO2 free) touring car where participants were given a broad impression of the possibilities for increasing the sustainability of energy use in the industry.

Number of meetings: 6 per year

Number of participants: 150 - 220

Participation inspiration tour: new business models CO2 reduction

In recent years VEMW, RVO and the NVDE have organized various inspiration tours to share knowledge and practical experience of the possibilities for reducing CO2 in industry. Companies were visited in a (CO2 free) touring car where participants were given a broad impression of the possibilities for increasing the sustainability of energy use in the industry.

Number of meetings: 6 per year

Number of participants: 150 - 220

Participation in inspiration tour: energy, innovation and climate funds

In recent years VEMW, RVO and the NVDE have organized various inspiration tours to share knowledge and practical experience of the possibilities for reducing CO2 in industry. Companies were visited in a (CO2 free) touring car where participants were given a broad impression of the possibilities for increasing the sustainability of energy use in the industry.

Number of meetings: 6 per year

Number of participants: 150 - 220

Participation in CO2 master class: current situation in combination with Triple C analysis

KWA Business Advisors and the Rijksdienst voor Ondernemend Nederland (RVO) invite you to participate in the second Masterclass series on CO2 reduction in the industry. The focus is on reducing energy and process emissions. We investigate what the best sustainability options are for your company and which schemes are appropriate. Because we think the Masterclass may be of interest to you, you will receive this special invitation!

Number of meetings: 4 per year

Number of participants: 20

Participation in CO2 master class: options for CO2 reduction with examples

KWA Business Advisors and the Rijksdienst voor Ondernemend Nederland (RVO) invite you to participate in the second Masterclass series on CO2 reduction in the industry. The focus is on reducing energy and process emissions. We investigate what the best sustainability options are for your company and which schemes are appropriate. Because we think the Masterclass may be of interest to you, you will receive this special invitation!

Number of meetings: 4 per year

Number of participants: 20

Participation in CO2 master class: own roadmap using fact sheets and regulations

KWA Business Advisors and the Rijksdienst voor Ondernemend Nederland (RVO) invite you to participate in the second Masterclass series on CO2 reduction in the industry. The focus is on reducing energy and process emissions. We investigate what the best sustainability options are for your company and which schemes are appropriate. Because we think the Masterclass may be of interest to you, you will receive this special invitation!

Number of meetings: 4 per year

Number of participants: 20