Machinery

Our machinery with hightech equipment & sustainable transport equipment

Machinery

High-tech equipment from Riwald Recycling for maximum raw material efficiency due to our Granulator, Infrared (NIR), X-ray, metal sensors, NF fines processing and colour sortings

Riwald Recycling hightech granulator

Our granulator, a unique metal processing machine, separates the ferrous from the non-ferrous. Due to its innovative operation system, our granulator with the linked waste separation technologies can separate the remaining waste from the incoming metals, resulting that all raw materials are suitable for 100% reuse.

Sennebogen 8160 EQ balance crane

Our Sennebogen 8160 EQ balance crane is equipped with the latest innovations for efficient operations. Thanks to the intelligent distribution of energy, this balance crane consumes less energy compared with regular cranes, leading to extensive energy savings within our business process based on the EQ principles.

Louritex PHGF-1000 scrap shear

Our Louritex scrap shear is a heavily constructed machine designed and developed in compliance with the latest technology in engineering and manufacturing standards. The Louritex scrap shear is characterized by its very high speed and affiliated production capacity.

Lefort 1400 scrap shear

Our Lefort 1400 scrap shear is a heavily constructed machine designed and developed in compliance with the latest technology in engineering and manufacturing standards. Our Lefort scrap shear is characterized by a special wider shear that ensures an even higher speed and affiliated production capacity.

Eddy currents for separation ferrous and non-ferrous

Our overband magnets, the magnetic head roller and the drum magnets sort and separate the iron types. In combination with our Eddy Currents with eccentric pool systems, valuable non-ferrous such as aluminium, copper and zinc will be recovered.

Drum sieve for separation ferrous and non-ferrous

Our drum sieve is used as the third step in the separation process. The output of our high-tech granulator is separated in our large drum sieve, where the metal is separated into ferrous and non-ferrous, which we subdivide into three different types of fractions.

Steindert Unisort for the separation of plastic, wood & printed circuit boards

Our magnets and Eddy Current separators can recover various metals, however, where magnetic separation reaches its limit, our sensor separation goes a step further. Certain properties such as color, shape and density can be detected, and a burst of compressed air shoots the detected particle out of our material flow. Due to our infrared, X-ray and plastic color detection a maximum raw material efficiency will be achieved.

Wetfloat separation for non-ferrous

Our wet separation system, also known as a water separation table, ensures that all our metal fractions will be recovered from our materials. The wet separation system, developed by Riwald Recycling, ensures that all our metal fractions from our materials will be recovered even more efficiently. Our water table is located after our high-tech granulator and ensures the separation of copper granulate from the plastic.

Steinert for color separation non-ferrous

Our magnets and Eddy Current separators can recover various metals, however, where magnetic separation reaches its limit, our sensor separation goes a step further. Certain properties such as color, shape and density can be detected, and a burst of compressed air shoots the detected particle out of our material flow. Due to our infrared, X-ray and plastic color detection a maximum raw material efficiency will be achieved.

Sensor separator for separation non-ferrous

Our magnets and Eddy Current separators can recover various metals, however, where magnetic separation reaches its limit, our sensor separation goes a step further. Certain properties such as color, shape and density can be detected, and a burst of compressed air shoots the detected particle out of our material flow. Due to our infrared, X-ray and plastic color detection a maximum raw material efficiency will be achieved.

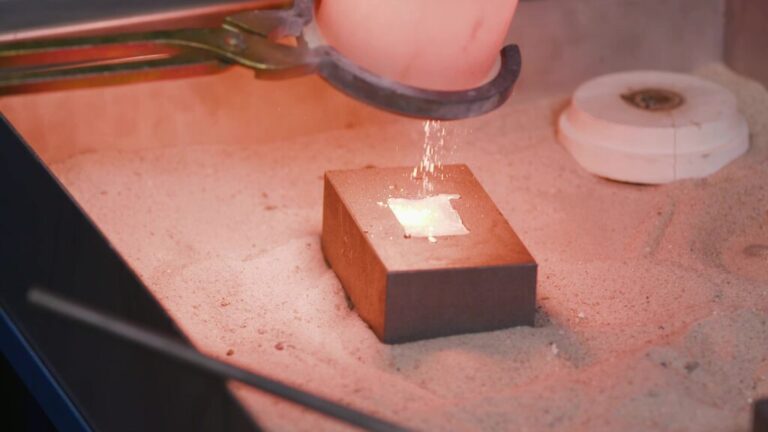

High-tech copper analysis with our spectrolyse

In our internal analysis centre, various copper samples will be made for the determination of the copper content. We make use of spectrolyse analysis and report the analysis reports to our customers.

Guidetti WIRE PRO cable granulator

Our Guidetti WIRO PRO cable granulating machine can process different types and thicknesses of industrial cables efficiently, and in combination with Guidetti cable recycling system 100% reuse will be realized.

Guidetti WIRE PRO hightech cable recycling

Our Guidetti WIRE PRO cable recycling system is an advanced cable granulating machine and separator for the separation of copper and aluminium.

PYROsmart detection system in combination with fire extinguishing guns

Riwald Recycling has been using the PYROsmart system since 2020. The PYROsmart system is an infrared system which can detect fire at an early stage. Where many other systems assume flames or extreme temperatures, the PYROsmart can detect a starting fire. Furthermore, the software works so well that it can effortlessly detect the difference between a fire and the hot parts of a transfer crane, e.g. the engine, exhaust or brakes. The software analyses the heat sources which are warmer than the alarm sets. On the basis of the temperature, movement and spot size, the software determines whether it is a disturbing object, heating, or a (starting) fire. Riwald Recycling uses the PYROsmart detection system in combination with extinguishing guns, which immediately fire when a fire starts. Thanks to these technological innovations, we stay a step forward in the recycling industry.

Sustainable transport

Sustainable transportation means from Riwald Recycling for the reduction of CO2 emissions.

Volvo FH with I-save

From January 2021 onwards, Riwald Recycling will transport with the latest Volvo FH trucks equipped with a highly efficient engine and a Long-Haul Fuel package, including innovative options e.g. I-See, I-Save and I-Shift for optimal fuel savings. With these investments, Riwald Recycling contributes to sustainable (inter)national metal transport and the global climate goals.

Scania Next Generation 2021

From January 2021 onwards, Riwald Recycling will transport with the brand new Scania Next Generation 2021 model, equipped with the newest digitalization towards energy reduction, leading to a more sustainable future. The new Scania Next Generation contributes to global climate goals

Volvo FH with I-save

From January 2021 onwards, Riwald Recycling will transport with the latest Volvo FH trucks equipped with a highly efficient engine and a Long-Haul Fuel package, including innovative options e.g. I-See, I-Save and I-Shift for optimal fuel savings. With these investments, Riwald Recycling contributes to sustainable (inter)national metal transport and the global climate goals.

Riwald Recycling Twillis transport boat for transporting various types of HMS

Riwald Recycling transports Heavy Metal Scrap (HMS) types 1/2, 2B and 3B by water with our Twillis transport boat, equipped with a sustainable diesel engine for minimal CO2 emissions.

Linde electric forklift trucks from the E35 and E50 series

Riwald Recycling likes to invest in innovative and environmentally friendly technologies. These electrically powered forklifts have a lower environmental impact and will replace diesel forklifts. This results in a strong CO₂ reduction. Motrac NL's new electric forklift trucks contain advanced technologies, with which the best results can be achieved in terms of safety, comfort, productivity, and sustainability.