Circular economy

Riwald Recycling & circular entrepreneurship

Circular entrepreneurship & Riwald Recycling

The contours of our business strategy lie in the Circular Framework and Trias Energetica. Circular Framework and Trias Energetica.

We link our sustainability strategies to the Sustainable Development Goals (SDGs) and we integrate innovative technologies for maximum raw material efficiency.

Circular Framework

- Circular entrepreneurship with the 9R strategies

Our business strategy originated from the combination of the Trias Energetica philosophy and the 3R philosophy, the predecessor of the 9R philosophy. The 3R philosophy is based on Recover, Reuse and Recycle of valuable ferrous ((steel, cast iron, stainless steel, with iron (Fe) as the main component)) and non-ferrous (aluminium, copper, lead, zinc, bronze, brass, all materials with another main component). Due to our efficient operations, in-house production process and geographic locations, Riwald Recycling occupies a prominent place in the recycling industry within the Netherlands and the rest of the world, both in the context of competitiveness and capacity. Our goal is to become a "circular hub" where all flows come together in our ecosystem - transforming complex products into pure raw materials and transporting these materials via a sustainable way to companies in the manufacturing industry. As result, the economy would run on recovered raw materials and ‘new’ raw materials would not be needed.

- 9R Circular Framework

- Recover, Reuse and Recycle of valuable ferrous and non-ferrous

- Efficient operations, in-house process and geographic locations

- Circular Hub

Trias Energetica

- In-house energy efficiency

With the Trias Energetica philosophy, the energy-efficient approach of Riwald Recycling is realized in the following three steps: 1) we limit the energy demand as much as possible; 2) we use renewable energy where possible; and 3) we meet the residual demand for energy as efficiently as possible with the help of fossil sources. Riwald Recycling continuously invests in a green future and makes use of a unique high-tech granulator in combination with linked separation technologies for maximum raw material efficiency. In addition, Riwald Recycling uses electric shears and cranes which are environmentally friendly, fuel-saving and noise-reducing. In combination with our sustainable transportation means, Riwald Recycling is one of the most innovative (metal) recycling companies within Netherlands and the rest of the world.

- Energy efficiency for maximum recovery

- Role model within the circular supply chain and energy transition

- Sustainable transport over land and water

- One of the most innovative (metal) recycling companies

Innovation in core technology

- Maximum resource efficiency thanks to our high-tech equipment

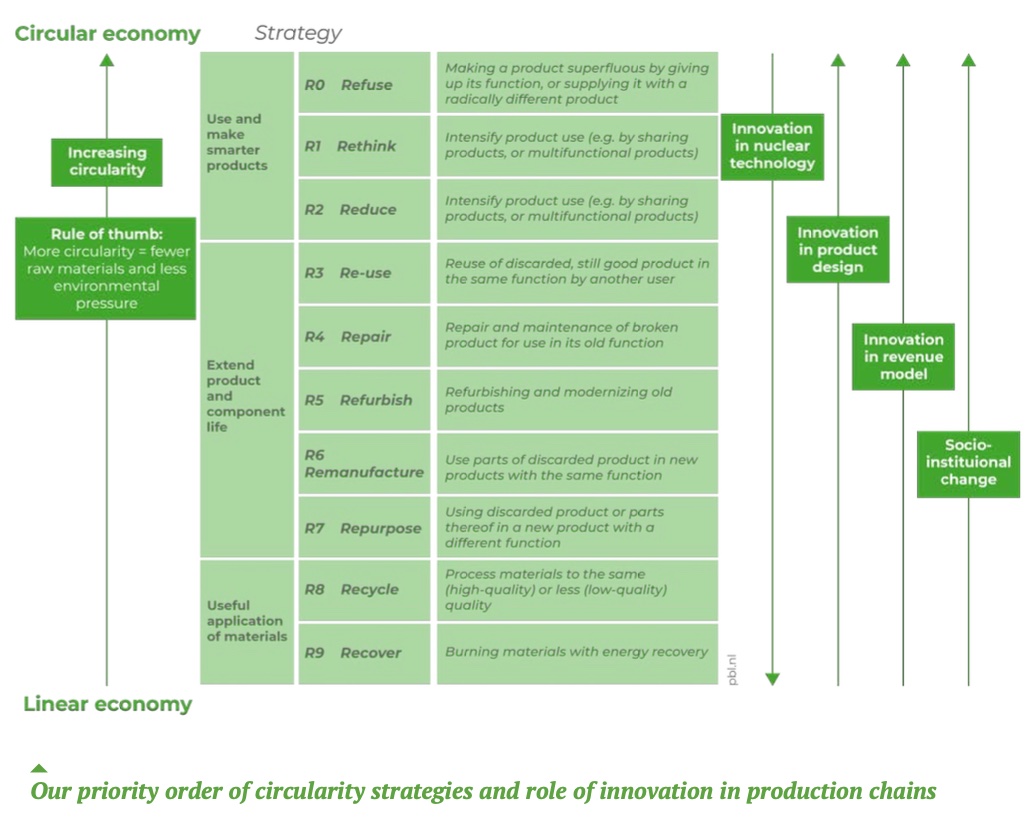

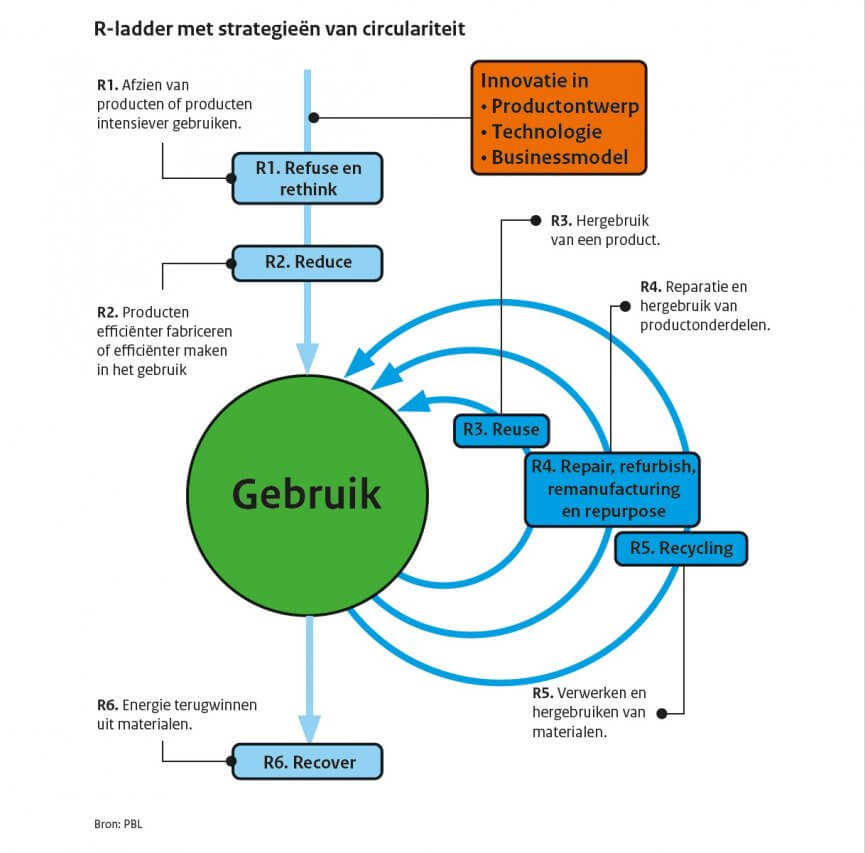

The PBL has mapped out the circular economy in the Netherlands with an inventory. The inventory consists of activities that (can) reduce the use of primary raw materials in the economy. The strategies as defined on the circularity ladder (R-ladder), such as refuse, reduce, repair and recycle, have been taken as the starting point for this. Based on our business strategy, consisting of the combination of the Trias Energetica philosophy and the 3R philosophy, Riwald Recycling invests in the latest developments, (separation and sorting) techniques, machines and equipment with the aim of processing materials to the same high quality.

Thanks to our high-tech granulator in combination with our high-tech equipment – double scrap shears, eddy currents, drum screens, wet separation tables, Infrared (NIR), X-Ray, metal sensors, NF fines processing and color sortings - we enhance raw material efficiency, resulting in that no 'new' raw materials are needed anymore, whereby materials are processed to the same high quality. The economy would then run on recovered raw materials and no 'new' raw materials would not be needed.

- R-Trap with strategies of circularity

- Circularity strategies and the role of innovation in the product chain

- Innovation in core technology

- Circular & High-tech recycling

Detection and robot sorting system for circular economy

High-tech detection system and picking robot to separate metals and waste types

- EFRO-OOST project - co-financed by the European Union

Due to rapid population growth and prosperity, the world needs more and more raw materials. The consequences are rising prices, a stagnant economy and the threat of depletion of critical raw materials. However, raw materials are essential for the global manufacturing industry, which now accounts for more than $16 trillion in turnover. Steel, cast iron, stainless steel, aluminum, copper, lead, zinc, bronze and brass are found in many complex products, such as mobile phones, cars, washing machines and advanced production processes. The demand for high-tech solutions to recycle these types of products is high, the quality requirements are high, and the availability of labor is decreasing.

Riwald Recycling, RIWO, Saxion University of Applied Sciences and TValley contribute to these challenges through an ERDF project. The consortium aims to “transform complex products into pure raw materials and to transport these logistics sustainably to companies in the manufacturing industry”.

- EFRO-OOST Project

- Riwald Recycling

- RIWO Engineering

- T-Valley

Circular Project

- In-house energy efficiency

Riwald recycles hundreds of thousands of tons of waste material every year, ranging from electronic waste, high-quality residual flows, to train sets and aircraft. Circular entrepreneurship is one of her core values. The ambition to make an even greater impact on the circular economy is strongly linked to the separation process. Using techniques such as granulators, scrap shears, eddy currents, water tables, choppers and sieves, Riwald sorts by induction, color and weight. This project is co-financed by the European Union.

However, at the end of the mechanical separation process, a flow of between 15 and 20 tons of non-ferous and waste types remains that can only be sorted manually for the time being. The causes are the large amount of different materials and the composition and entanglement of the materials. At this time, manual sorting of this material flow is the only option; There is simply no detection and sorting technology that autonomously and automatically makes an unambiguous selection of materials.

- One of the most innovative (metal) recycling companies

- Energy efficiency for maximum recovery

- High-tech R&D projects for the circular economy

- Role model within the circular supply chain and energy transition

Waste does not exist

- Reduction of primary raw materials

The preliminary research shows, among other things, that a combination of detection and sorting technologies can separate the (residual) flows completely automatically. A system that contributes significantly to the transformation towards a circular economy. By 2030, the Netherlands wants to use 50% less primary raw materials (including metals) and by 2050 our economy must be completely circular. In concrete terms, this means: 'An economy in which as many sustainable renewable raw materials are used as possible, products and raw materials are reused and in which waste does not exist.'

- Stimulation of % recycling

- Reduction of primary raw materials