News

Latest news about Riwald Recycling Almelo & Beverwijk

Riwald Recycling & news

Latest news in the field of sustainability, circular economy, efficient operations, projects and the latest innovations in connection with Riwald Recycling Almelo & Beverwijk

Twee weken geleden ontvingen we KBO van Reutum en Haarle voor een rondleiding bij Riwald Recycling Netherlands

- 26-10-2025

Afgelopen week hebben we de katholieke bond voor ouderen (KBO) uit Reutum en Haarle mogen ontvangen voor een rondleiding. Met deze rondleiding willen wij iets terugdoen voor de generatie die de Nederlandse industrie in de afgelopen jaren hebben opgebouwd én deze te informeren hoe we tegenwoordig hoogwaardig recyclen t.b.v. circulaire economie en schaarste aan grondstoffen. In een grote groep hebben zij eerst een presentatie over Riwald bijgewoond en daarna een rondleiding over onze werf in Almelo gekregen.

Stap voor stap lieten wij zien hoe verschillende afvalstromen hoogwaardig gerecycled worden naar zuivere grondstoffen.Het was een zeer geslaagde ochtend met enthousiaste ouderen, en de verbinding tussen de generaties maken deze rondleidingen bijzonder

RIWALD RECYCLING STAPT MET HAAR WAGEN- EN MACHINEPARK OVER OP HV100 & REDUCEERT CO2

- 17-1-2025

Wij maken graag een positieve impact op het milieu en op de samenleving. Onze missie is om een schonere wereld achter te laten voor de volgende generatie. We zijn dan ook trots dat wij de overstap hebben gemaakt naar HVO100 (Hydrotreated Vegetable Oil) brandstof. Met deze overstap draagt bij aan duurzaam (inter)nationaal verwerking & transport waarbij we onze CO2-emissies en CO2 voetprint reduceren 📉

HVO is een hernieuwbare brandstof gemaakt van afval- en reststromen, zoals plantaardige oliën en dierlijke vetten. Het biedt een milieuvriendelijk alternatief voor de traditionele diesel. In tegenstelling tot fossiele brandstoffen is HVO vrijwel volledig CO2-neutraal, wat betekent dat de uitstoot van broeikasgassen tijdens het gebruik aanzienlijk wordt verminderd.

Dankzij HVO-brandstof kunnen we onze CO2-uitstoot met wel 90% verminderen. Hiermee draagt Riwald bij aan het decarboniseren van de metaalindustrie, wat in lijn is met onze CO₂-Prestatieladder Niveau 5. Naast de CO2-reductie verlaagt HVO ook de uitstoot van fijnstof en stikstofoxiden (NOx), wat zorgt voor een schonere lucht.

Deze innovatie maakt ons een duurzame keuze voor onze partners en helpt het om projecten te realiseren die voldoen aan de hoogste eisen voor energieprestatie en milieuvriendelijkheid.

Samen bouwen we aan een groene toekomst waarin duurzaamheid de norm is, zonder concessies te doen aan kwaliteit en efficiëntie 🌍

Samenvoeging verschillende BVs naar Riwald Recycling Netherlands & launch nieuw logo

- 28-11-2024

🇳🇱 Met genoegen brengen wij u op de hoogte van de nieuwe ontwikkelingen binnen Riwald Recycling. Vanaf 1-11-2024 gaan de bedrijven Riwald B.V., Riwald Non Ferro (Hijma), Riwald Corporate Branding B.V., Riwald Recycling Beverwijk B.V., en Riwald Recycling Exploitatie B.V. verder onder de naam Riwald Recycling Netherlands B.V. (voorheen Riwald Exploitatie B.V.).

Deze juridische fusie - samenvoeging - is ingegeven om de Nederlandse structuur te vereenvoudigen en administratieve lasten te verminderen. Alle contracten van voorgenoemde BVs worden van rechtswege overgenomen door Riwald Recycling Netherlands B.V. met bijbehorende rechten en plichten. Voor u blijft alles verder zoals u gewend bent, met dezelfde contactpersonen en service.

De visuele wijziging die plaatsvindt is ons nieuwe logo met passende huisstijl die beter aansluit én uniformiteit creëert binnen de recycling bedrijven van ons moederbedrijf ArcelorMittal, waarbij Riwald Recycling dé merknaam wordt voor huidige & toekomstige recycling vestigingen in Europa.

🇬🇧 We are pleased to inform you regarding the new developments within Riwald Recycling. From 1-11-2024, the companies Riwald B.V., Riwald Non Ferro (Hijma), Riwald Corporate Branding B.V., Riwald Recycling Beverwijk B.V., and Riwald Recycling Exploitatie B.V. will continue under the name Riwald Recycling Netherlands B.V. (previously Riwald Exploitatie B.V.).

This legal merger - amalgamation - was initiated to simplify the Dutch structure and reduce administrative burdens. All contracts of the aforementioned BVs are automatically taken over by Riwald Recycling Netherlands B.V. with associated rights and obligations. Everything for you will continue as you are used to, with the same contact persons and service.

The visual change that is taking place is our new logo with an appropriate house style which fits better and creates uniformity within the recycling companies of our parent company ArcelorMittal, with Riwald Recycling as brand name for current and future recycling locations in Europe.

🇩🇪 Wir freuen uns, Sie über die neuen Entwicklungen bei Riwald Recycling zu informieren. Ab dem 1. November 2024 sind die Unternehmen Riwald B.V., Riwald Non Ferro (Hijma), Riwald Corporate Branding B.V., Riwald Recycling Beverwijk B.V. und Riwald Recycling Exploitatie B.V. weiter bekannt unter dem Namen Riwald Recycling Netherlands B.V. (ehemals Riwald Exploitatie B.V.).

Diese rechtliche Fusion – Zusammenlegung – soll die niederländische Struktur vereinfachen und den Verwaltungsaufwand verringern. Alle Verträge der oben genannten BVs werden automatisch von Riwald Recycling Netherlands B.V. übernommen. mit den damit verbundenen Rechten und Pflichten. Für Sie läuft alles wie gewohnt weiter, mit den gleichen Ansprechpartnern und dem gleichen Service.

Die optische Veränderung, die stattfindet, ist unser neues Logo mit einer passenden Corporate Identity, die besser passt und Einheitlichkeit innerhalb der Recyclingunternehmen unserer Muttergesellschaft ArcelorMittal schafft, wobei Riwald Recycling zum Markennamen für aktuelle und zukünftige Recyclingbranchen in Europa wird.

Verruiming Twentekanaak - stimulans voor de regionale economie & CO2-reductie

- 4-10-2024

Het Twentekanaal in Overijsel verbindt de havens in Twente met de havens in Rotterdam, Amsterdam en Antwerpen. Rijkswaterstaat is verantwoordelijk voor het onderhoud van deze belangrijke logistieke schakel naar de rest van Europa. Met een toename in niet alleen het aantal vrachten over water, maar ook de grootte en zwaarte van de schepen, is voor een vlotte en veilige doorvaart verruiming van de hoofd- en zijtak noodzakelijk.

De afgelopen jaren is er hard gewerkt om het Twentekanaal geschikt te maken voor grotere schepen. Met de verruiming van de Twentekanalen kunnen nu grotere en zwaarder beladen schepen veiliger en vlotter varen en zijn de havens van Almelo, Hengelo en Enschede beter bereikbaar. Dit is een stimulans voor de regionale economie en werkgelegenheid alsmede vermindering van de CO2-uitstoot.

Als watergebonden bedrijf is het Twentekanaal cruciaal voor Riwald Recycling. Naast de transformatie van complexe producten naar pure grondstoffen zorgt de verruiming ook een CO2-reductie per ton schroot, waarbij onze grondstoffen getransporteerd en hergebruikt worden door bedrijven in de (maak)industrie. In het filmpje hiernaast kijkt o.a. onze bedrijfsleider Bart van Kessel terug op een geslaagd project met alle betrokken partijen.

Afgelopen zaterdag was het tijd voor ons jaarlijkse personeelsfeestje

- 29-07-2024

Samen met alle collega's hebben we een fantastische dag gehad! We begonnen met een zeer uitgebreide lunch, gevolgd door een intense ‘Expeditie Robinson’ waar verschillende kampen tegen elkaar streden voor de winst! We eindigden de dag met een BBQ waar we heerlijk gegeten hebben en sloten af met een besloten feest met live muziek 🍹🎶

Namens de organisatie bedanken wij iedereen voor het enthousiasme en inzet!

Verjonging van ons wagenpark met de nieuwe Volvo FH met Fuel-Save

- 4-04-2024

Wij hebben ons wagenpark verjongd met een nieuwe Volvo FH540 Globetrotter XL met Fuel-Save. Een vrachtwagen die het icoon vormt voor de lange afstand, met een ruime cabine waarin het comfort voor de chauffeur centraal staat i.c.m. innovatieve veiligheidsfuncties.

Deze nieuwe Volvo FH truck is uitgerust met Tridemstel en VDL 30T haaksysteem, geleverd door VDL Container Systems bv en geïnstalleerd door Brinks Carrosserieën. Met deze investering draagt Riwald Recycling bij aan duurzaam (inter)nationaal metaal transport en reduceren wij onze O2-emissie en CO2 voetprint.

Wij danken alle betrokken organisaties voor de opbouw en Walter Peters namens de Nijwa BV voor de levering en prettige samenwerking. Wij wensen onze trucker Jos Rikhof veilige kilometers toe.

Ewald Huzink na 34 als directeur/mede-oprichter met pensioen samen met collega's

- 05-01-2024

Op zondag 31 december 2023 heeft Ewald Huzink een punt gezet achter zijn werkzame jaren als algemeen directeur/medeoprichter bij Riwald Recycling . Het bedrijf aan de Buitenhaven Oostzijde is uitgegroeid tot een complex van 7 hectare, vol hightech scheidingsapparatuur en -technologie voor maximale terugwinning uit grondstoffen. Ewald stond samen met zijn broer Gert Huzink aan het roer stond bij familiebedrijf Riwald Recycling, inmiddels onderdeel van ArcelorMittal - de op één na grootste staalproducent ter wereld. Het merk 'Riwald' zal wereldwijd door ArcelorMittal worden gepositioneerd in de recycling/downstream-markt.

Op 22 december nam Riwald Recycling officieel afscheid van Ewald Huzink als grondlegger van Riwald. ’s Avonds waren familie, vrienden en collega’s aanwezig om op informele wijze terug te kijken op 34 jaar Riwald Recycling. Op dezelfde avond hadden we ook het afscheid genomen van onze gewaarde collega’s Bertie Wiegman en Peter Stuifbergen i.v.m. het behalen van de pensioengerechtigde leeftijd. De dagelijks werkzaamheden van Ewald worden overgedragen aan het management team, waarbij Sylvia Lammertink zal optreden als CFO van Riwald Recycling.

Namens het gehele team enorm bedankt voor de prettige samenwerking, inzet en betrokkenheid.

DETECTION AND ROBOTIC SORTING SYSTEM FOR CIRCULAR ECONOMY

- 8-12-2023

Due to rapid population growth and prosperity, the world needs more and more raw materials. The consequences are rising prices, a stagnant economy and the threat of depletion of critical raw materials. However, raw materials are essential for the global manufacturing industry, which now accounts for more than $16 trillion in turnover. Steel, cast iron, stainless steel, aluminum, copper, lead, zinc, bronze and brass are found in many complex products, such as mobile phones, cars, washing machines and advanced production processes. The demand for high-tech solutions to recycle these types of products is high, the quality requirements are high, and the availability of labor is decreasing.

Circulair ondernemen

Riwald recyclet jaarlijks honderdduizenden tonnen afvalmateriaal, variërend van elektronisch afval, hoogwaardige reststromen, tot treinstellen en vliegtuigen. Circulair ondernemen is een van haar kernwaarden. De ambitie om nog meer impact te maken op de circulaire economie is sterk verbonden met het scheidingsproces. Met technieken als granulatoren, schrootscharen, eddy currents, watertafels, hakmolens en zeven sorteert Riwald op inductie, kleur en gewicht. Aan het einde van het machinale scheidingsproces resteert echter een stroom van tussen de 15 en 20 ton non-ferous en afvalsoorten die vooralsnog enkel handmatig kan worden gesorteerd. Oorzaken zijn de grote hoeveelheid verschillende materialen en de samenstelling en verstrengeling van de materialen. Op dit moment is handmatig sorteren van deze materiaalstroom de enige optie; er bestaat gewoonweg nog geen detectie- en sorteertechnologie die autonoom en automatisch een eenduidige selectie maakt van de materialen.

The preliminary research shows, among other things, that a combination of detection and sorting technologies can separate the (residual) flows completely automatically. A system that contributes significantly to the transformation towards a circular economy. By 2030, the Netherlands wants to use 50% less primary raw materials (including metals) and by 2050 our economy must be completely circular. In concrete terms, this means: 'An economy in which as many sustainable renewable raw materials are used as possible, products and raw materials are reused and in which waste does not exist.'

Samenwerking

TValley heeft als innovatiecluster de verbinding gelegd tussen Riwald Recycling en de twee TValley partners RIWO en Hogeschool Saxion. De komende drie jaar werken onderzoekers van Saxion, studenten, engineers van RIWO, subsidieconsultants van Leap en domeinspecialisten van Riwald Recycling samen aan het ontwikkelen van slimme sensoren, algoritmes en robotica om de reststroom van non-ferous en afvalsoorten autonoom en zuiver te scheiden

This involves a completely new high-tech detection system and picking robot to separate metals and waste types. The results of the subsidy project consist of (1) acquiring domain and material knowledge, (2) realizing various detection and robot sorting modules, (3) a circular recycling chain and (4) an operational product that is ready for market introduction.

This project is co-financed by the European Union.

Staff party Riwald Recycling 2023

- 2-8-2023

Last Saturday it was time for our staff party! We had a fantastic day together with all our colleagues! We started on the karting track where everyone tried to beat each other and set the fastest lap time, followed by intense 'outdoor paintball games'. We ended up in Bistro de Kruidentuin where we had a delicious meal and ended with a private party with live music.

With this staff party we have already started our construction holiday, which will start next Friday after the construction drinks! A well-deserved holiday for everyone to enjoy the sun, sea, beach or simply in the garden.

''We MUD samen vedan!”

- 10-07-2023

Last Saturday, colleagues from Riwald Recycling participated in Tot de Nek in de Drek. A 7.5 kilometer course with obstacles was completed in tropical temperatures with the encouragement of the supporters. Great afternoon of team building!

Expansion of our fleet with Linde Electric forklift truck E35 - E50

- 14-6-2023

We have expanded our fleet with new electric forklift trucks from the Linde E35 and E50 series. They will be used for internal transport, especially when moving heavy material flows.

Riwald Recycling likes to invest in innovative and environmentally friendly technologies. These electrically powered forklifts have a lower environmental impact and will replace diesel forklifts. This results in a strong CO₂ reduction. Motrac NL's new electric forklift trucks contain advanced technologies, with which the best results can be achieved in terms of safety, comfort, productivity, and sustainability.

Riwald Recycling featured on DISCOVERY+

- 06-06-2023

The new season of Mighty Truckers follows the 'lives on the road' of truckers from different countries. Eef Verhaag is one of these truckers and shows her world of transport within metal recycling at Riwald Recycling. She explores the whole country in her huge truck cab and drives the ten-ton truck like it is nothing!

In the program, Eef was followed in her daily work. The trucker's life is quite tough and not always easy. For example, Eef has to deal with busy roads and some risks that can occur in the profession. She initially got her truck driver's license to transport her horses, in the program she tells how she ended up in the beautiful world of transport.

She says the following about her participation: “It was a special experience, the truck was full of cameras, there was a video crew present and a car drove along that also films everything. It was fun to participate. I am curious about the episodes and also curious about the other participants.”

<br Eef Verhaag en Riwald Recycling zijn te zien in Mighty Truckers op 1 en 8 augustus. Kijk jij ook mee?

Collaboration with Riwald Recycling and Aveleijn

- 28-4-2023

At Aveleijn we are committed to good care and a healthy planet. Circularity is an important part of a greener future. Many raw materials can be extracted from electronic devices that can be reused. This is better for the earth than extracting new raw materials. In collaboration with the processing company Riwald Recycling, we collect old electronic devices from which the raw materials are reused for new products. Our clients from the garden team are involved in the collection process and receive a demonstration by Riwald, so they discover which substances can be reused to make new products.

Inleveren van je huishoudelijke apparatuur kan vanaf maandag 1 mei tot en met vrijdag 19 mei. We zijn op werkdagen tussen 09:00 en 15:30 uur aanwezig. De container is te vinden op de parkeerplaats van het Bestuurscentrum in Borne.

The attached flyer shows which devices can be returned.

After the period at the administrative center, the container goes to the next region to collect electronic devices there. Which region would collect the most?

LOGISTICS CAFÉ: BUSINESS VISIT AT RIWALD RECYCLING

- 01-03-2023

On Thursday, February 23, a company visit to Riwald Recycling was organized by the Logistic Association of Port of Twente. Riwald Recycling was able to share its knowledge and vision through a tour and a presentation led by Ewald Huzink and Bart van Kessel. The visit ended with a networking drink!

To strengthen logistics with other companies in the Twente region, make it more sustainable and support the Twente economy, Riwald Recycling is a member of Port of Twente.

As a water-related company, the Twente Canal, as well as road transport in the region, is extremely important. Riwald Recycling is therefore happy to work with Port of Twente and its members for the shared interest of good infrastructure.

End-Of-Waste Certificates

- 6-2-2023

The Dutch economy must be completely circular by 2050. To achieve that goal, reuse must be taken into account when designing new products. It must also be ensured that existing products can be recycled as much as possible at the end of their life cycle. The recycling sector plays a crucial role in this.

When closing material cycles, it is essential that waste streams that are suitable for this purpose can be reused. However, once a material is 'waste', it cannot simply be used as a secondary raw material. In order to achieve high-quality use of these raw materials, agreements are required on, among other things, the 'End-Of-Waste' status of materials and products, but also on the quality requirements that must be imposed on secondary raw materials for safe and healthy application.

Thanks to our advanced processing and separation techniques, Riwald Recycling has obtained its End-of-Waste certificates with the criteria of European Regulations 333/2011 and 715/2013. With these certificates, Riwald Recycling demonstrates that they can process iron, steel, aluminum and copper scrap into pure raw materials, which can be used directly in the production process of new metals. This step furthers our position in sustainability and circularity

Rebuilding update location Almelo

- 09-12-2022

Het aftellen is begonnen! Nog een paar weken en dan hopen wij dat de verbouwing van het kantoorpand klaar is. De schilders zijn druk bezig geweest om de muren te voorzien van een frisse kleur. Deze week wordt er hard gewerkt aan het plaatsen van het interieur door De Pander.

Zijn jullie net zo nieuwsgierig naar het eindresultaat als wij? Houd de socials in de gaten.

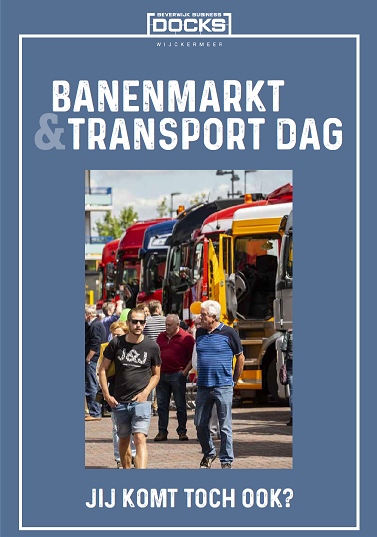

Co₂-Performance ladder level 5

- 18-11-2022

Riwald Recycling is at the top of the CO₂ performance ladder.

Working sustainably is not just a buzzword for us, but also daily practice. We take CO2 reduction seriously and want to make a contribution. We do this by working on targets that will reduce our CO2 emissions every year. We reduce our CO2 emissions by implementing various energy-saving measures in the office and at our high-tech complex. We measure our performance with the CO₂-Performanceladder.

Recycling of metals partially avoids the production of metals from primary raw materials (ores). This leads to savings in CO₂ emissions compared to production of primary metals. It therefore makes sense in the context of climate policy to ensure that metal is recycled, as this avoids production of metals from primary raw materials.

Deze week ontvingen wij als eerste metaalrecyclingbedrijf van Nederland de CO₂-Prestatieladder Niveau 5 voor onze vestigingen Almelo en Beverwijk. De CO₂-Prestatieladder is een managementsysteem van de SKAO (Stichting Klimaatvriendelijke Aanbesteden & Ondernemen) en is in het leven geroepen om bedrijven te stimuleren CO₂-bewust(er) te handelen. De CO₂-Prestatieladder is hét duurzaamheidsinstrument van Nederland dat bedrijven en overheden helpt bij het reduceren van CO₂ en kosten, binnen de bedrijfsvoering, in projecten én in de keten.

Rebuilding update location Almelo

- 10-11-2022

We are now six weeks into the renovation work. The renovation of our office building is making good progress. A lot of work has been done in recent weeks, including plastering the walls, laying the new floor and installing the glass walls that create an open atmosphere.

Are you also so curious about the sequel? Keep an eye on the socials for more updates on the renovation.

National Recycle Week

- 14-10-2022

Since 2 June 2022, there has been a collaboration between Riwald Recycling, Slim Opgewekt and Aveleijn. A pilot project has been launched for the collection and recycling of E-waste. E-waste is all waste electrical and electronic equipment (WEEE). This educational project combines awareness about circularity with a physical collection campaign by Aveleijn, with Riwald Recycling recycling these products into renewable raw materials.

What is collected? At day care centre De Roos in Goor, there is a container where local residents can hand in their e-waste including mobile phones, coffee machines, audio and video equipment, ovens, microwaves and fans. The proceeds from the container are for day care centre De Roos.

On Thursday 13 October, Ömer Avci visited Aveleijn in Goor on behalf of Riwald Recycling. Among other things, the recycling process of a washing machine was explained to the clients.

Rebuilding update location Almelo

- 12-10-2022

The renovation of Riwald Recycling's office building is in full swing. We are now three weeks down the line.

Are you also so curious about the sequel? Keep an eye on the socials for more updates on the renovation.

Once again, the Netherlands is extremely dry

- 15-9-2022

Once again it is extremely dry in the Netherlands. We also notice the impact of this at Riwald.

"Normally we do a lot more via barges, at the moment we really have to go to trucks because the water level is too low," said Ewald Huzink, director of Riwald Recycling.

Attached is the full news item on Riwald Recycling from the Nieuwsuur

WEEELABEX (CENELEC) Certificate type 1,2 en 3

- 29-08-2022

Led by Bart van Kessel, a successful WEEELABEX audit was conducted resulting in Riwald being a Type 3 processor in addition to Type 1 and 2!

The procedure for treating and handling e-waste is defined by the WEEELABEX quality standard (CENELEC standards). An organisation can obtain WEEELABEX certification when it can demonstrate compliance with specific requirements when treating and processing e-waste. Certification is via a comprehensive audit and a batch test.

Three types of processors are currently certifiable through WEEELABEX Organisation: Type 1️⃣ Manual processing and depollution

Type 2️⃣ Mechanical processing and depollution

Type 3️⃣ Advanced and specialised machine processing and depollution

Riwald Recycling is the only one in the Netherlands to hold a WEEELABEX CENELEC Type 1, Type 2 and Type 3 certificate for Large White Goods (LHA) and Small Domestic Electrical and ICT Equipment (SHA).

Banenmarkt & Transportdag | 17 & 18 Juni te Beverwijk

- 13-6-2022

On Friday June 17 and Saturday June 18, our team from Riwald Recycling will be ready for you at the Jobs and Transport Day in Beverwijk.

With more participants than ever, 25 (transport) companies from the region will show that Beverwijk is the hotspot of Transport and Logistics in the IJmond region on Saturday, June 18 from 10:00 to 17:00. Around the Kop van de Haven at the Parallelweg, the transport companies and shippers will show off their best trucks, delivery vans and special vehicles. On the terraces around a festive party ship, everyone can get to know the transport companies and there is plenty for the kids to do. It will become clear that a job in this sector is a great way to earn a nice living.

On June 17, the day before Transport Day, a large Job Fair will be held at the same location from 10:00 to 16:00 for all Beverwijk companies.

Expansion of our fleet with the Volvo FH500 Globetrotter with I-Save

- 09-06-2022

We have expanded our fleet with a Volvo FH500 Globetrotter XL with I-Save. A truck that is the icon for the long haul, with a spacious cabin in which the comfort of the driver is central i.c.m. innovative safety features.

The latest Volvo FH trucks are equipped with D13TC power source, so with turbo-compound technology and a Long Haul Fuel package, consisting of innovative options, including I-See, I-Save and I-Shift for optimal fuel economy. With these investments, Riwald Recycling contributes to sustainable (inter)national metal transport and we reduce our CO2 emissions and CO2 footprint.

We thank Nijwa Groep BV and Nijhof-Wassink for the delivery and the good cooperation and wish our Ladytrucker Eef Verhaag safe kilometers.

Expansion of our machine park with the Sennebogen 830E transfer crane

- 25-5-2022

We have expanded our machine park with an electric Sennebogen 830E transshipment crane equipped with the latest innovations for efficient operations. This advanced crane is used during transshipment operations at our granulator, which then granulates and separates the metallic products - ranging from end-of-life electronic devices to railcars and airplanes - from the ferrous and non ferrous metals.

Jarmo Koopman is the operator of the new Sennebogen 830E transshipment crane. ''I followed the crane operator training for three years and after completing my training I had the ambition to drive a large crane. This ambition has been fulfilled within Riwald and I am also grateful to Riwald for this opportunity and role within the recycling process.''

As of 2016, Riwald Recycling may call itself an accredited training company. The cooperation with the Stichting Samenwerking Beroepsonderwijs Bedrijfsleven (SBB) ensures that education and business are combined for good practical training. Riwald Recycling has trained several BBL/BOL students, a number of which are also employed by Riwald Recycling within various departments.

Riwald Recycling: our loyal employee

- 26-04-2022

Last Friday we proudly celebrated the reach of the retirement age of three of our valued colleagues. We celebrated the years of dedication of Joke Doctor, Ewald Robel and Theo Jansen and their contribution to the success of Riwald Recycling. 💪

On behalf of the entire team, thank you very much for the pleasant cooperation, effort and commitment. Jos will continue to work part-time within the company as a crane driver.

Riwald Recycling and the Week of Circular Economy

- 12-02-2022

In Overijssel many great things are already happening in the field of circularity! In cooperation with the Province of Overijssel, we are happy to pay attention to circularity during the Week of the Circular Economy.

Raw materials are finite and for this reason we must use them sparingly. The Dutch government has set the goal: Netherlands fully circular by 2050, an economy without waste, where everything runs on reusable raw materials.

As a leading metal recycling company, Riwald Recycling plays a pivotal role as a supplier in the circular chain of sustainable material use. ''We contribute to the creation of a circular economy and thus to the achievement of the government's objectives, especially with the prospect of increasing demand for raw materials, virgin materials are becoming increasingly scarce, said Gert Huzink.''

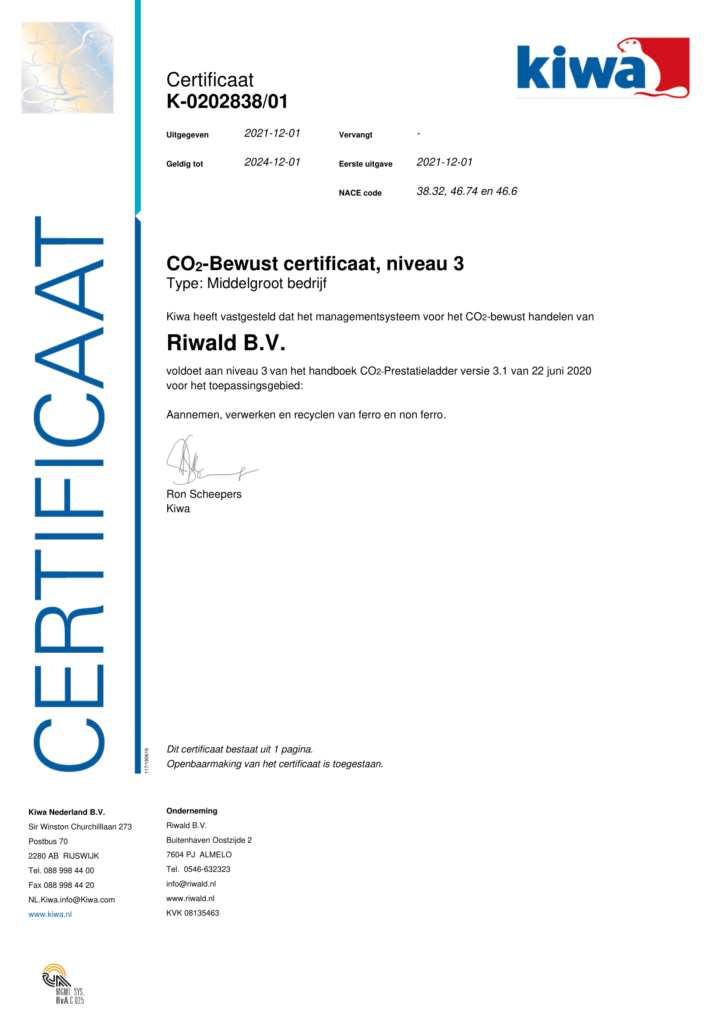

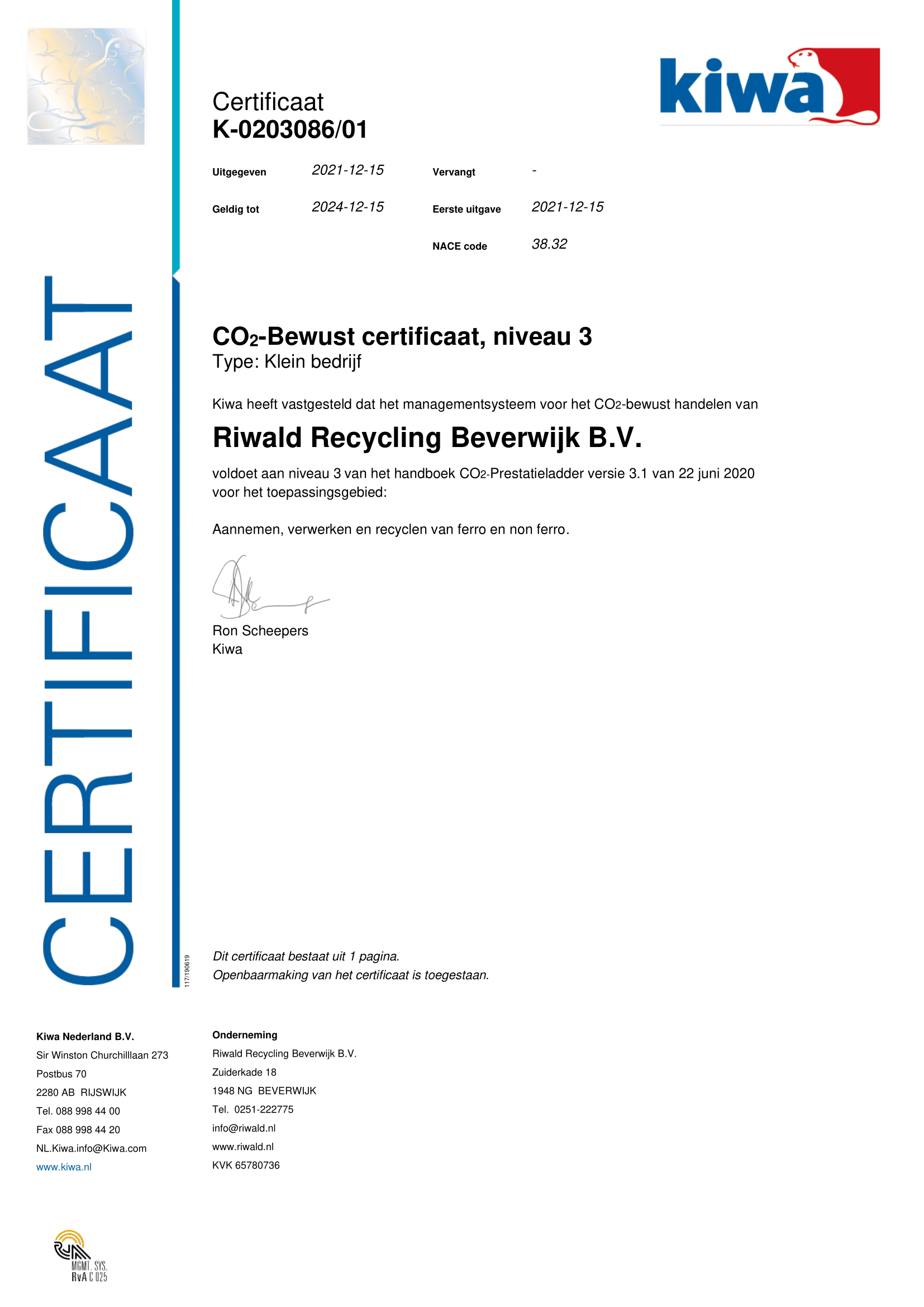

Riwald Recycling obtains CO2-Performanceladder certificate for its Almelo and Beverwijk sites

- 21-01-2022

Our world faces major, complex and urgent challenges. High CO2 emissions are leading to climate change and our natural resources are becoming increasingly scarce. This requires a different way of producing and consuming. By recycling complex products, Riwald Recycling forms a connecting link in the circular economy and we ensure significant CO2 savings in the chain.

Working sustainably is not just a buzzword for us, but also daily practice. We take CO2 reduction seriously and want to make a contribution. We do this by working on targets that will reduce our CO2 emissions every year. We reduce our CO2 emissions by implementing various energy-saving measures in the office and at our high-tech complex. We measure our performance with the CO₂-Performanceladder.

Afgelopen maand ontvingen wij het CO₂-Prestatieladder certificaat voor onze beide vestigingen, Almelo en Beverwijk. De CO2-Prestatieladder is een managementsysteem van de SKAO (Stichting Klimaatvriendelijke Aanbesteden & Ondernemen) en is in het leven geroepen om bedrijven te stimuleren CO2-bewust(er) te handelen. De CO₂-Prestatieladder is hét duurzaamheidsinstrument van Nederland dat bedrijven en overheden helpt bij het reduceren van CO2 en kosten, binnen de bedrijfsvoering, in projecten én in de keten.

Riwald Recycling Beverwijk has once again actively participated in the Week of Industrial Culture

- 28-10-2021

Riwald Recycling Beverwijk has once again actively participated in the Week of Industrial Culture, organized by Industriecultuur. During this week, company visits were organized at exciting industrial sites in the North Sea Canal area, our Beverwijk branch could not miss out on this year either.

The event exists since 2015 and every year Riwald offers company visits during this period. As far as we are concerned, this week was again a huge success in which we were able to receive two groups. In this way, we give visitors a unique opportunity to take a look at our metal recycling process, and we try to convey the importance of our work. Every year again a great opportunity for young and old!

The guided tours were given under the supervision of Richard Heimering.

Entrepreneur magazine: 'on the road to one hundred percent circular recycling'

- 14-10-2021

In the new edition of the Entrepreneurial Magazine Municipality of Tubbergen, Ewald and Gert Huzink talk about their future prospects for the company Riwald Recycling. Riwald wants to be the circular hub for metal flows and play an active role in finding solutions to international environmental issues.

Riwald is engaged in innovation in the areas of electrification, efficient use of raw materials, sustainable production and transportation. These topics are covered in detail in the article.

Riwald Recycling: our loyal employees

- 13-9-2021

Last Friday, we proudly celebrated three of our valued colleagues reaching their retirement age. We celebrated the many years of dedication of Joke Doctor, Ewald Robel and Theo Jansen and their contribution to the success of Riwald Recycling. Joke, Ewald and Theo: on behalf of the entire team, thank you so much for your pleasant collaboration, efforts and involvement. All three of you are great people! Joke and Ewald will continue to work for the company. Theo will also always be welcome for any work or a cup of coffee.

Sustainable transport with our new trucks: Volvo FH with I-save

- 16-8-2021

After the receivement of the first new Volvo FH 2021 model with I-Save, Riwald Recycling will transport with two Volvo FH models with I-Save from January 2021 onwards. The newest Volvo FH trucks are equipped with a highly efficient engine and a Long Haul Fuel package including innovative options, under which I-See, I-Save and I-shift for optimal fuel savings. With these investments, Riwald Recycling contributes to sustainable (inter)national metal transport and reduces its CO2-emmision and CO2 footprint.

University of Groningen issues certificate to Riwald Recycling

- 8-7-2021

Since this week, we as Riwald Recycling, have our own Radiation Protector Officer (RPO). A Radiation Protection Officer (RPO) Measurement and Control Technique must supervise work with encapsulated radiation sources and/or X-ray equipment subject to a license or registration requirement and forms the link between the work floor and the management/radiation protection team.

.

Congratulations to Ömer Avci on completing the course 'Radiation Protection Measurement and Control Applications', conducted at the University of Groningen.

Governor of Bonaire brings a working visit to Riwald Recycling

- 22-6-2021

Last Saturday, June 19, Riwald Recycling received the Lieutenant Governor of Bonaire, Edison Rijna, on a working visit in Almelo. Under the leadership of Ewald Huzink, Gert Huzink and Bart van Kessel, the Lieutenant Governor of Bonaire and the Mayor of Almelo, Arjen Gerritsen, were shown around the high-tech complex of Riwald Recycling and proudly showed its latest innovations in the field of metal recycling.

''As one of the leading metal recycling companies, Riwald Recycling plays a pivotal role as a supplier in the circular chain of sustainable material use worldwide. Thanks to our experience, our wide range of recycling options and our commitment to environmental, social and corporate governance criteria, Riwald Recycling ranks among the most advanced, respected and trusted recycling companies in the Netherlands and the rest of the world, says Ewald Huzink. ''

We would like to share our vision and knowledge within the Kingdom of the Netherlands, including Bonaire. Bonaire faces significant challenges in the field of (metal) waste processing. Waste processing infrastructure needs to be improved and investments in recycling are a high priority. Due to the urgency and the demand for an even more sustainable waste policy, the Lieutenant Governor of Bonaire, Edison Rijna, visited Riwald Recycling, where Riwald plays an active role in finding solutions to Bonaire's environmental issues. Riwald Recycling links its sustainability strategies to the Sustainable Development Goals (SDGs) and integrates innovative technologies for maximum recovery from raw materials. Currently, the first containers with e-waste and scrap are being loaded in Bonaire for transport to the Netherlands, and Riwald Recycling is responsible for the transformation of complex products into pure raw materials with the objective: ''that the Dutch economy would run on recovered raw materials and that no more 'new' raw materials are needed'', says Ewald Huzink.

Sustainable operations with our Fuchs MHL390F transfer crane

- 20-5-2021

Our machinery consists of several cranes, including a Fuchs MHL390F transfer crane, which is equipped with the latest innovations for efficient operations. Thanks in part to the intelligent distribution of energy, there is an optimal ratio between maximum capacity and low fuel consumption, leading to considerable energy savings within our business process.

Riwald Recycling experts in firefighting

- 19-3-2021

Riwald Recycling has been using the PYROsmart system since 2020. The PYROsmart system is an infrared system which can detect fire at an early stage. Where many other systems assume flames or extreme temperatures, the PYROsmart can detect a starting fire. Furthermore, the software works so well that it can effortlessly detect the difference between a fire and the hot parts of a transfer crane, e.g. the engine, exhaust or brakes. The software analyses the heat sources which are warmer than the alarm sets. On the basis of the temperature, movement and spot size, the software determines whether it is a disturbing object, heating, or a (starting) fire. Riwald Recycling uses the PYROsmart detection system in combination with extinguishing guns, which immediately fire when a fire starts. Thanks to these technological innovations, we stay a step forward in the recycling industry.

Riwald Recycling partner of Klimaatplein

- 24-2-2021

Riwald Recycling's circular solutions have a prominent place in the metal recycling industry within the Netherlands and the rest of the world. Riwald Recycling is the "circular hub" for metal flows. Nowadays, these solutions are also visible at the Klimaatplein. On a monthly basis, the Klimaatplein is visited twenty thousand times by organizations that want to do more sustainable business. Visitors will find many practical stories from companies that actively reduce their CO2 emissions and/or do circular business.Riwald Recycling is not only a partner, but also a participant in the Climate Action Alliance of the Klimaatplein. This Alliance consists of 70 SMEs that jointly work on a 40% CO2 reduction within 5 years.

Sustainable transport with our new Scania Next Generation 2021

From January 2021 onwards, Riwald Recycling will transport with the brand new Scania Next Generation 2021 model, equipped with the newest digitalization towards energy reduction, leading to a more sustainable future. The new Scania Next Generation contributes to global climate goals

- 17-1-2021

Sustainable transport with our new trucks: Volvo FH with I-save

From January 2021 onwards, Riwald Recycling will transport with the latest Volvo FH trucks equipped with a highly efficient engine and a Long-Haul Fuel package, including innovative options e.g. I-See, I-Save and I-Shift for optimal fuel savings. With these investments, Riwald Recycling contributes to sustainable (inter)national metal transport and the global climate goals.

- 14-1-2021

Sustainable operations with our new Sennebogen 8160 EQ balance crane

- 09-1-2021

Riwald Recycling expands its fleet with an electric Sennebogen 8160 EQ balance crane which is equipped with the latest innovations for efficient operations. Thanks to the intelligent distribution of energy, this balance crane consumes less energy compared with regular cranes, leading to extensive energy savings within our business process based on the EQ principles

Riwald Recycling celebrates its centenary with 30 years of progress

- 30-09-2019

Riwald Recycling celebrated its 30th anniversary this weekend. 30 years ago, the brothers Gert, Ewald and Richard Huzink started recycling metal scrap. In this day and age, Riwald Recycling consists of two sites and the company supplies the worldwide demand for ferrous and non-ferrous. Riwald Recycling hosted a big event for all our relations and busines partners. More than 600 people attended our event, with Humberto Tan as guest speaker. The next day there was an open day for all curious persons.

Riwald Recycling donates 30.000 euros to Poverty Pact Almelo

- 28-9-2019

During a unique conference hosted by the Poverty Pact Almelo, Riwald Recycling donated ten checks with a total value of 30.000 euros to ten initiatives. These organizations are directly committed to people who live in poverty. According to Ewald Huzink, ‘the poverty pact has existed for 10 years and we therefore thought it would be a nice gesture to choose 10 initiatives’. These are the meal providers Eethoek, Ter Wille, the addiction care, which helps to forced prostitutes, Leergeld Almelo and Tubbergen, who ensure that children in poverty can still go to school.